Monocrystalline Silicon

Monocrystalline silicon has two crystalline forms, crystalline and amorphous. Crystal silicon can be further divided into monocrystalline silicon and polycrystalline silicon, both of which have a diamond lattice structure. This crystal is hard and brittle, has a metallic luster, and is conductive, although not as conductive as metals. It exhibits semiconductor properties that change with temperature.

Monocrystalline silicon is an essential foundational material in modern science and technology, used in everyday electronic devices and control systems. Items like televisions, computers, refrigerators, phones, watches, and cars are closely associated with monocrystalline silicon materials. Monocrystalline silicon, as one of the popular materials for technological applications, has permeated every aspect of people's lives.

Polycrystalline Silicon

Polycrystalline silicon is a form of elemental silicon. When molten elemental silicon solidifies under supercooled conditions, silicon atoms arrange themselves into multiple crystal nuclei in a diamond lattice structure. If these nuclei grow into grains with different crystal orientations, they combine and crystallize into polycrystalline silicon.

Polycrystalline silicon can be used as a raw material for pulling monocrystalline silicon, and the main differences between polycrystalline silicon and monocrystalline silicon are primarily in their physical properties. For instance, in terms of mechanical performance, optical performance, and thermal performance, any anisotropy is less pronounced in polycrystalline silicon compared to monocrystalline silicon. Regarding electrical performance, the conductivity of polycrystalline silicon crystals is much lower than that of monocrystalline silicon, and it may even have poor conductivity.

Differences

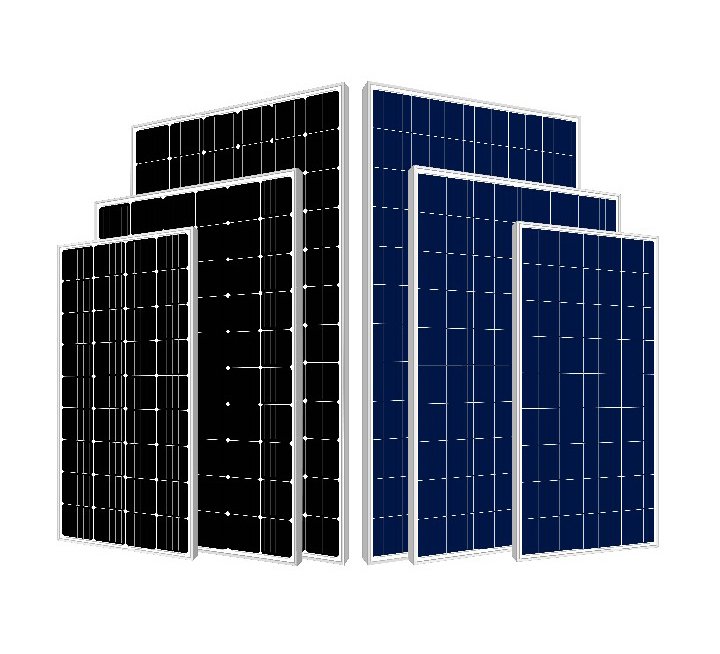

Differences in Appearance

The four corners of monocrystalline silicon solar cells are curved, with no patterns on the surface, and they appear deep blue, almost black. In contrast, the four corners of polycrystalline silicon solar cells are angular, with patterns resembling frost flowers on the surface, and they appear sky blue, with vibrant colors.

Differences in Usage

For end users, there isn't a significant difference between monocrystalline silicon and polycrystalline silicon solar cells in terms of lifespan and stability. Monocrystalline silicon solar cells have a slightly higher average conversion efficiency compared to polycrystalline silicon, but they are currently more expensive than polycrystalline silicon.

Differences in Manufacturing Process

Polycrystalline solar cells require fewer manufacturing steps than monocrystalline solar cells, which means that slightly less energy is consumed during the production process of polycrystalline silicon solar cells. However, monocrystalline solar cells produce higher electricity generation, and when considering the overall energy consumption, the difference is not significant.

Comparison Between Monocrystalline and Polycrystalline

Monocrystalline solar panels were used before polycrystalline panels, but the current situation is that polycrystalline silicon's use in power plants far exceeds that of monocrystalline silicon, with monocrystalline silicon accounting for 30% and polycrystalline silicon 70%. In terms of efficiency, monocrystalline panels are more efficient than polycrystalline panels, with efficiency rates ranging from approximately 10% to 20%. Monocrystalline panels are slightly more expensive than polycrystalline ones, with costs varying among manufacturers, and market prices ranging from five cents to ten cents per watt. Regarding degradation rates, empirical data shows that both monocrystalline and polycrystalline panels have their advantages, and it is challenging to determine degradation solely based on their crystal structure. Instead, product quality factors like sealing, impurities, and hidden cracks have a greater impact on degradation rates. In terms of value for money, currently, polycrystalline panels offer slightly better value than monocrystalline panels, but this may change in the future as monocrystalline panel costs decrease, potentially leading to a reversal in the market."

OWELL Industries is a company committed to providing innovative power generation solutions. Specializing in wind and solar power systems, OWELL offers a diverse range of products, including wind turbines, solar panels, and associated components and accessories. With a strong focus on energy transition and sustainable development, OWELL actively contributes to the global shift towards cleaner and more environmentally friendly energy sources.

Their comprehensive product portfolio caters to a wide spectrum of needs, serving both residential and industrial sectors. OWELL Industries stands as a reliable partner in advancing the adoption of renewable energy technologies, delivering value and exceptional services to customers seeking to harness the power of wind and solar for a greener future.

Quick Link:

5kW vertical axis wind turbine

10kW horizontal axis wind turbine

High Efficient Monocrystalline 50-500W Solar Panels

high efficient Polysilicon solar panels 50-500W solar panels