In accordance with the maintenance manual for gas generator sets, it is essential to periodically disassemble the gas generator set into various components. Each component should be meticulously inspected for signs of aging and wear. Additionally, it is crucial to clean the surfaces of the components from dust and oil residue. Any severely worn or distorted components should be promptly replaced. To ensure prolonged durability, a uniform application of rust preventive oil on component surfaces is recommended. Moreover, it is imperative to replace malfunctioning devices such as water pump seals, cylinder sleeve temperature sensors, thermostats, and starter motors.

Once confirmed that all components are in optimal condition, the next step is to sequentially reassemble the components into a fully operational gas generator set. A detailed examination of the installation of each component, relative positioning, and interval distances is necessary. Following the assembly, a functional test should be conducted under various operating conditions. Upon successful testing, the preventive maintenance work is considered complete, and the gas generator set can be put into operation.

Furthermore, a comprehensive analysis taking into account factors such as the usage lifespan, historical operational conditions, and fault occurrence rates is essential. Implementing a tiered technical maintenance system allows for different levels of disassembly and inspection procedures. This approach not only achieves the desired preventive maintenance effects but also reduces the workload associated with generator set maintenance, avoiding disruptions to normal operations caused by frequent disassembly and inspections.

For instance, using cumulative working hours as a tiered standard, first-level technical maintenance should be performed when the cumulative working hours of the gas generator set reach 1000 hours. Second-level technical maintenance is recommended at 500 hours, and third-level technical maintenance should be conducted when the cumulative working hours reach either 1000 or 1500 hours.

By following these preventive measures, gas generator sets can operate efficiently, ensuring prolonged lifespan and minimizing the risk of unexpected failures.

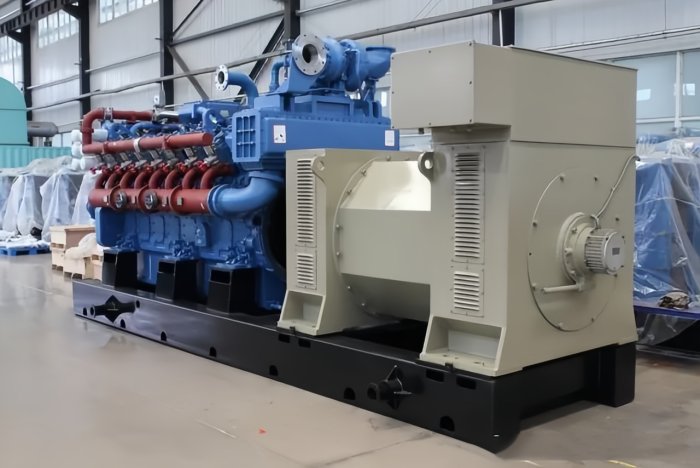

In a world where reliable power is an absolute necessity, OWELL Industries stands out as a beacon of power solutions excellence. With a commitment to quality and a dedication to serving global markets, OWELL is your trusted partner for top-tier gas generators that meet CE and ISO quality standards. When it comes to ensuring uninterrupted power, OWELL is the name you can depend on.

A World of Power Awaits with OWELL

When you choose OWELL's gas generators, you're choosing a power solution that combines innovation, reliability, and sustainability. Make a smart investment in your power needs and join the growing community of OWELL users worldwide.

Don't compromise on power. Choose OWELL's gas generators and experience the peace of mind that comes with uninterrupted, eco-friendly energy. Whether you're in need of prime power, standby power, or continuous power, OWELL has you covered.

Unlock the power of tomorrow today. Contact OWELL Industries and take the first step towards a more sustainable and reliable future. For inquiries and more information, visit OWELL's website and let your power needs meet their perfect match with OWELL.

Quick Link:

OWELL 33KVA-1375KVA Gas Generator Powered by WEICHAI

4000 Series (1320-2200KW) Gas Engine Generator

OWELL Industrial Gas Generator