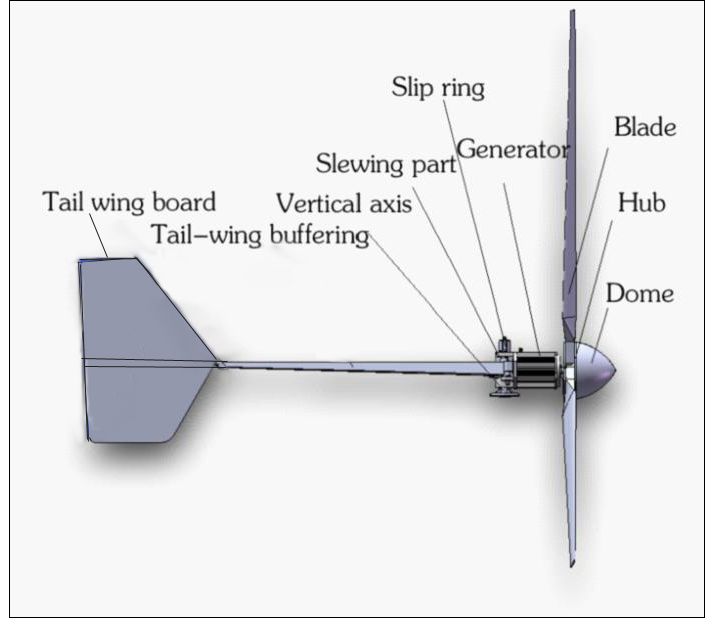

Horizontal axis wind turbines can be defined into two types: lift type and drag type. The lift type has a faster rotation speed than drag type. For wind power generation, lift-type horizontal axis wind turbines are mostly used. Most horizontal axis wind turbines have yawing devices, which can rotate with the change of wind direction. For small wind turbines, yawing device uses a tail vane, while for large wind turbines, use commonly transmission device consisted of wind direction sensing elements and servo motor

The wind turbine with the wind wheel in front of the tower is called the upwind wind turbine, and the one with the wind wheel behind the tower is called the downwind wind turbine.

The horizontal axis wind turbine has a long history of development, and it has fully achieved working production, with a simple structure and higher efficiency than vertical axis wind turbines. So far, almost all wind turbines used for power generation are horizontal axis.

OWELL industries is devoted ourselves to wind energy, design and supply horizontal axis wind turbine from 50W-200KW with CE and ISO quality standards.

Why you choose OWELL

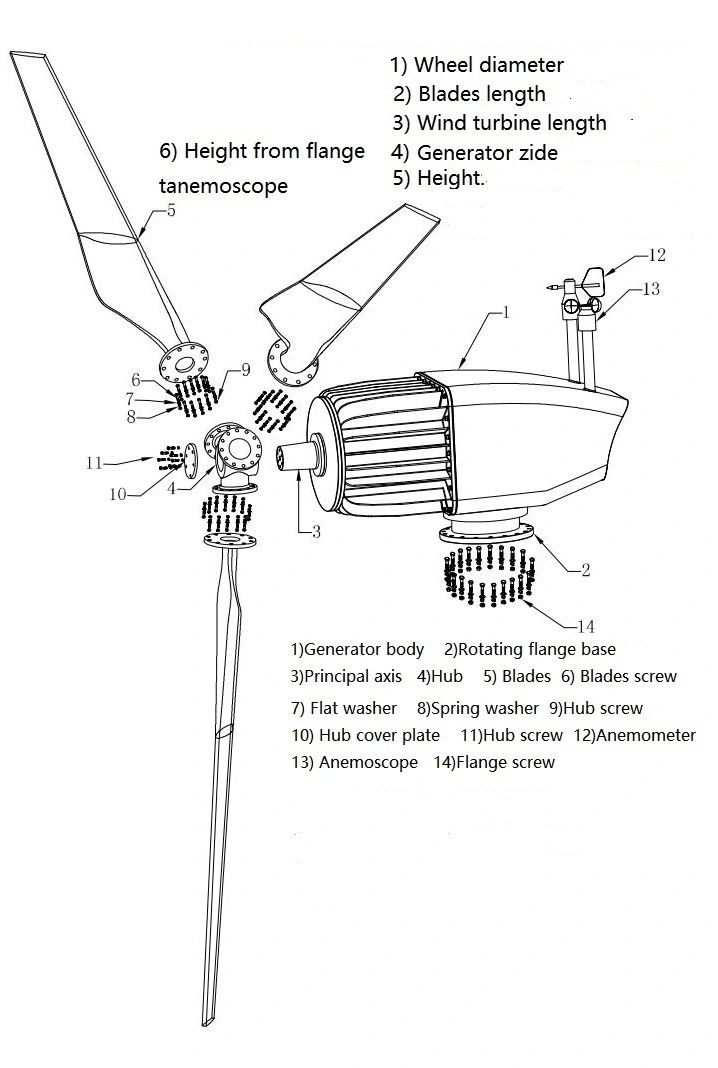

1. Safety: The main stress point of the blade is concentrated on the hub, so the problems of blade falling, breakage and blade flying out have been better solved

2. Wind resistance ability: horizontal rotation makes it less exposed to wind pressure and can resist super typhoons at 45 meters per second

3. Radius of gyration: Due to different design structure and operating principle, it has a smaller gyration radius than other types of wind turbine, which saves space and improves efficiency

4. Power generation curve characteristics: the start-up wind speed is lower than other types of wind turbines, and the increase of power generation is relatively gentle. Therefore, within the range of 5 to 8 meters wind speed, the power generation is 10%~ 30% higher than other types of wind turbines

5. Brake device: The blade has speed protection, and can be equipped with mechanical manual and electronic automatic brakes. In areas without typhoons and super gusts, only manual brakes are enough

6. The housing is made of A3 steel, which is small in size, light in weight, beautiful in appearance, and low in operating vibration.

7. Flange installation. good strength, convenient installation and maintenance.

8. Fiber reinforced plastic wind turbine blades, coupled with optimized aerodynamic shape design and structural design, low start-up wind speed, high wind energy utilization coefficient, better annual power generation.

9. The tail vane adopts automatic yaw design, folding tail type, stronger anti-typhoon ability, safe and reliable operation.

10. Turbine uses the patented neodymium iron boron permanent magnet rotor alternator. equipped with a special rotor design, which effectively reduces the resistance torque of the generator. It is only 1/3 of the ordinary motor, and makes the wind wheel and the alternator have better matching characteristics. This improves reliability of generator operation.

11. Optional power tracking intelligent controller, which can effectively adjust the current and electricity